3M Products & Supplies

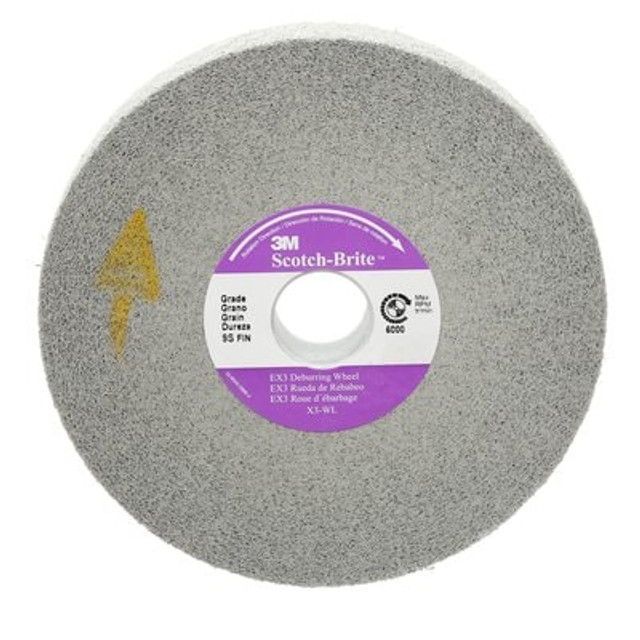

Scotch-Brite EX3 Deburring Wheel, X3-WL, 9S Fine, 6 in x 1 in x 1 in, 3 ea/Case

Scotch-Brite EX3 is an effective wheel to deburr, blend, finish and polish edges on glass, hard and soft composites, and metals such as builder's hardware, medical instruments, metal fabrication, metal implants, plumbing fixtures, and turbine engines. Because of its hard density, we do not recommend the EX3 for applications where conformability and finishing of flat surfaces are required.

Scotch-Brite EX3 Deburring Wheel is available with silicon carbide or aluminum oxide abrasive mineral. Silicon carbide is a synthetic mineral that is very sharp and commonly used for low-pressure applications such as paint prep and finishing. Aluminum oxide is a hard, blocky mineral that provides high cut-rate and long life. While silicon carbide breaks down faster than aluminum oxide, it produces a finer finish.

Our Scotch-Brite industrial abrasives are unique surface conditioning products with abrasives incorporated into non-woven nylon or synthetic fibers. Combining abrasives with the fibers creates an abrasive system that delivers consistent results for the life of the product. The open-web material runs cool and is load resistant, which keeps the abrasive minerals cutting at high performance by limiting clogging of the fibers.