3M Products & Supplies

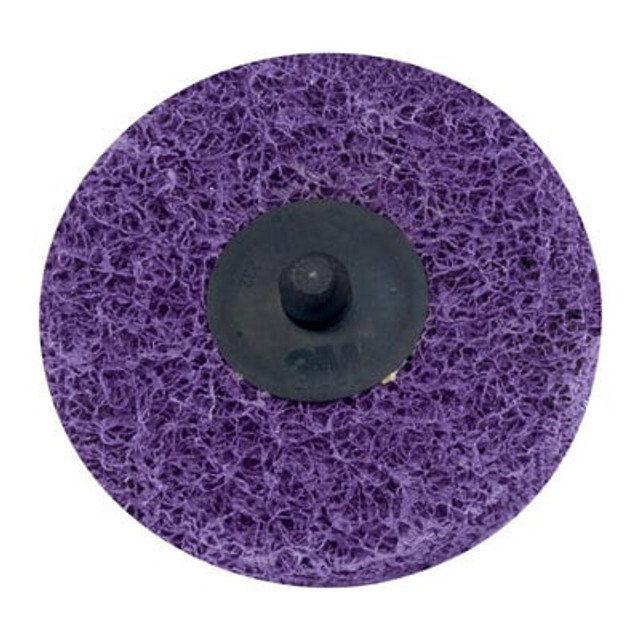

Scotch-Brite Roloc HS Blend and Finish Disc, TR, 3 in x NH A MED, 25/Carton, 100 ea/Case

Made with Aluminum Oxide

Scotch-Brite Roloc Cut and Polish Disc is engineered using aluminum oxide, which is a popular choice among industrial professionals because of its cut-rate and long life. This mineral is tough, durable and self-fractures to expose fresh cutting edges in use, whereas traditional minerals, such as garnet, quickly wear down with use. Due to its high cut-rate, hardness, strength, and low heat retention, aluminum oxide mineral is widely used in grinding applications in addition to sanding and finishing use. Aluminum oxide is suitable on a wide variety of substrates in both woodworking and metalworking, including ferrous alloys.

Roloc Attachment

For swift and easy disc change out during multi-step sequences, we gave this abrasive disc a Roloc attachment. 3M Roloc TR discs are smaller discs that have a plastic threaded button or screw designed to easily and quickly screw onto a Roloc TR disc pad (sold separately). Securing and detaching the disc to the backup pad is as simple as a twist-on and twist-off. The Roloc system provides a secure attachment even for heavy-duty applications, and the variety of available 3M Roloc discs allows swapping from one application to the next in seconds.

The Many Benefits of Scotch-Brite Abrasives

Our Scotch-Brite abrasives are unique surface conditioning products with minerals incorporated into non-woven fiber matrix. Combining abrasives and non-woven material creates an abrasive system that delivers consistent results for the life of the product. The open-web material runs cool and is load resistant, which keeps the abrasive minerals cutting at high performance by limiting clogging of the fibers.